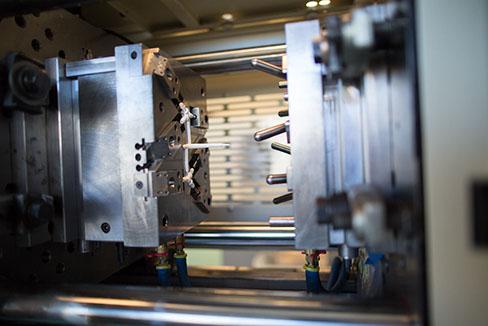

TOOL MAKING

ARC has the expertise to design and build the highest quality MIM and plastics injection molding tools. We utilize state-of-the-art, high-speed, 5-axis CNC machines to create custom molds and tooling. Tooling produced includes quick turn modular tooling through class 101 and everything in between. ARC’s in-house tool building team welcomes diverse mold standards and shape complexities with exceptional precision.

COMPOUNDING

ARC facilities have full in house compounding and mixing capabilities. A variety of both planetary and high shear mixing processes are utilized to ensure consistently uniform feedstocks and color blends. To guarantee consistent material quality, a proprietary computerized weighing system is utilized. All material is subjected to a battery of tests including rheology and density. This precision process allows the successful manufacturing of complex materials like tungsten, 718, other nickel/cobalt super-alloys.

INJECTION MOLDING

ARC has 92 electric and hydraulic molding machines ranging in size from 17 ton to 500 ton. Machine producers include Arburg, Battenfeld, Cincinnati, Nissei, Toshiba and Toyo. Machine are equipped with automation including full 6-axis high speed robot cells to perform value add work. ARC maintains a ISO Class 8 certified cleanroom for molding and assembly of medical devices. The range and magnitude of machines, facilities and automation ensures that there is an injection molding solution at ARC for your project.

DEBINDING

ARC’s variety of debinding capabilities provides several options for improved dimensional control. We utilize 12 solvent chambers with precision integrated control logic and industrial automation. We also have 7 thermal debind furnaces for high precision micro parts and one catalytic system.

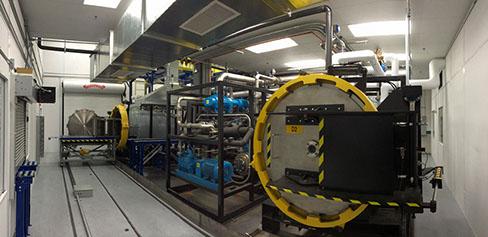

SINTERING

ARC has enormous sintering capabilities allowing us to provide dimensional stability and high capacity. We have an in house manufacturing line dedicated to manufacturing custom sintering fixtures to support the complex parts through the sintering process. Our scale is unmatched with 21 large scale vacuum sintering furnaces with both Moly and Graphite hot zones as well as 9 atmospheric retort furnaces. If your volume is 1,000 or 10,000,000 ARC has the sintering capacity to support you.

CNC MACHINING, PRECISION GRINDING, ASSEMBLY AND SECONDARY OPERATIONS

To support tolerances which cannot be held in sintering, or to achieve un-moldable geometries such as internal undercuts, ARC employs (20) precision grinders, (20) 3 and 4-Axis CNC mills, (2) precision 5-Axis CNC mills, (3) wire EDM machines, (3) sinker EDM machines, (7) high resolution vision systems, and a multitude of other specialized processing equipment to ensure your precise requirements are met.

Our dedicated assembly areas and keen focus on lean manufacturing provide turnkey sub-assembly options for all of our injection molded components.