MIM SCHOOL

LEARN MIM FROM THE PROFESSIONALS

MIM School started as a training class targeted towards customers, potential customers, new employees and vendors who had an interest in learning more about the MIM process. Since its inception in 2005, ARC has trained over 250 “students” on the basics of Metal Injection Molding. The seminar walks attendees through all aspects of MIM from powders and compounding to secondary processes by using both classroom instruction and hands-on training on the manufacturing floor.

By getting the attendees out on the floor, they are exposed to not only the sales pitch but also the technical area specialists who perform the work on a day-to-day basis which allows them to gain confidence in the MIM process at Advanced Forming Technology.

Along with walking through the MIM process, MIM School also delves into the engineering of a MIM part and provides information on designing a part for the MIM process. So, for customers not familiar with the MIM process or how to convert a different technology to be MIM friendly, this class provides that assistance and puts customers in touch with our expert staff.

Since our acquisition by ARC Group Worldwide, we have added content that exposes attendees to the other varied technologies under the ARC Group umbrella including Plastic Injection Molding, Clean Room Molding, Tool/Die Making, Metal Injection Molding, Rapid Prototyping for Manufacturing.

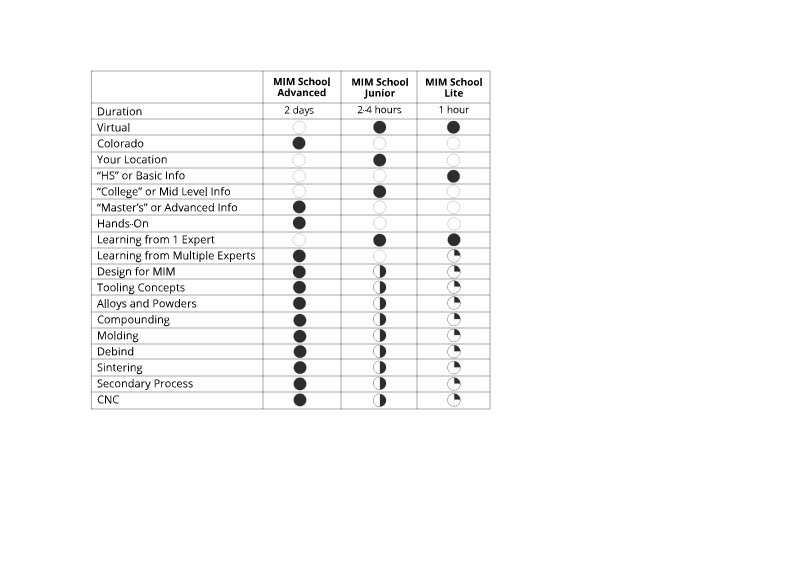

In addition to the training at our facility, we can also tailor a class on-site for customers who have a larger group for the training. This class can be modified from something as short as a simple lunch-and-learn or go as long as a full day depending on the needs and availability of the customer.

MIM SCHOOL DATES

| Month | In-Person |

|---|---|

| February | 21st - 22nd, 2024 |

| May | 1st - 2nd, 2024 |

| August | 21st - 22nd, 2024 |

| November | 13th - 14th, 2024 |

DAY 1

ARCMIM INTRODUCTION

The companies, our speakers and the program objective

POWDERS AND COMPOUNDING

Raw material characteristics and the compounding of metal powders

MIM INJECTION MOLDING

The unique challenges of metal injection molding using reciprocating screw machines

DESIGNING FOR MIM

The basic design principals, part consolidation, and general tolerance rules for MIM parts

DAY 2

MANUFACTURING STEPS

Debind, Sintering and Restage: Theory and participation

QUALITY

PPAP, NPI Process and Certifications

SECONDARY OPERATIONS

Coining, Heat Treat, and Machining

FINAL REVIEW

AIRPORT DEPARTURE